Augmented Reality at Boeing

Determined how to safely integrate the Microsoft Hololens into Boeing’s manufacturing systems. Adapted augmented reality technology as a tool to make routing aircraft electrical systems easier for aircraft electricians.

Project Outcomes and Impact

This project ended up being a huge success for Boeing. What started as a small site project eventually blossomed into an enterprise project that made Boeing a leader in industrial use applications of augmented reality technology. Here as some business outcomes we were able to achieve with this project:

- 30% improvement in workflow time

- 70% improvement in quality

- 12 use case replications across the company

- Zero employee injuries as a result of research testing

- A reduction in long-term ergonomic risk exposure for employees

Background

How Aircraft Electricians Do Their Work

Aircraft electricians complete their work by following printed text instructions with attached 2-D diagrams.

They also have the option to utilize 3-D CAD modeling for reference purposes when it is available.

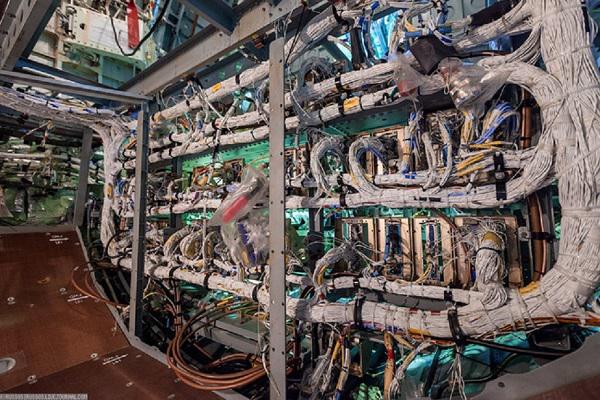

They are responsible for routing thousands of wires through aircraft structuring. Spatial reasoning and fine motor skills are used to route wires by hand.

The work can only be completed by hand and it is a manufacturing trade that takes years to be come an expert in.

The Situation

The KC-46A Pegasus Tanker is a military refueling aircraft with one of the most complex electrical systems in the world.

When I worked on this production line, I observed how aircraft electricians struggled daily with the electrical wiring of this aircraft.

The employees in my workplace were tasked to remove all the wiring from the first 20 production units and re-installing with updated engineering specifications over a three year period.

Boeing’s Research & Technology division assessed if there were any prototype tools that could be used to help my aircraft electricians with this work.

There had been some preliminary lab work demonstrating successful use of the Microsoft Hololens to help with electrical wiring.

Before we knew it, our leadership was asking how we could adapt this prototype tool safely from R&D to full use on the production line.

Human Factors and Safety Research

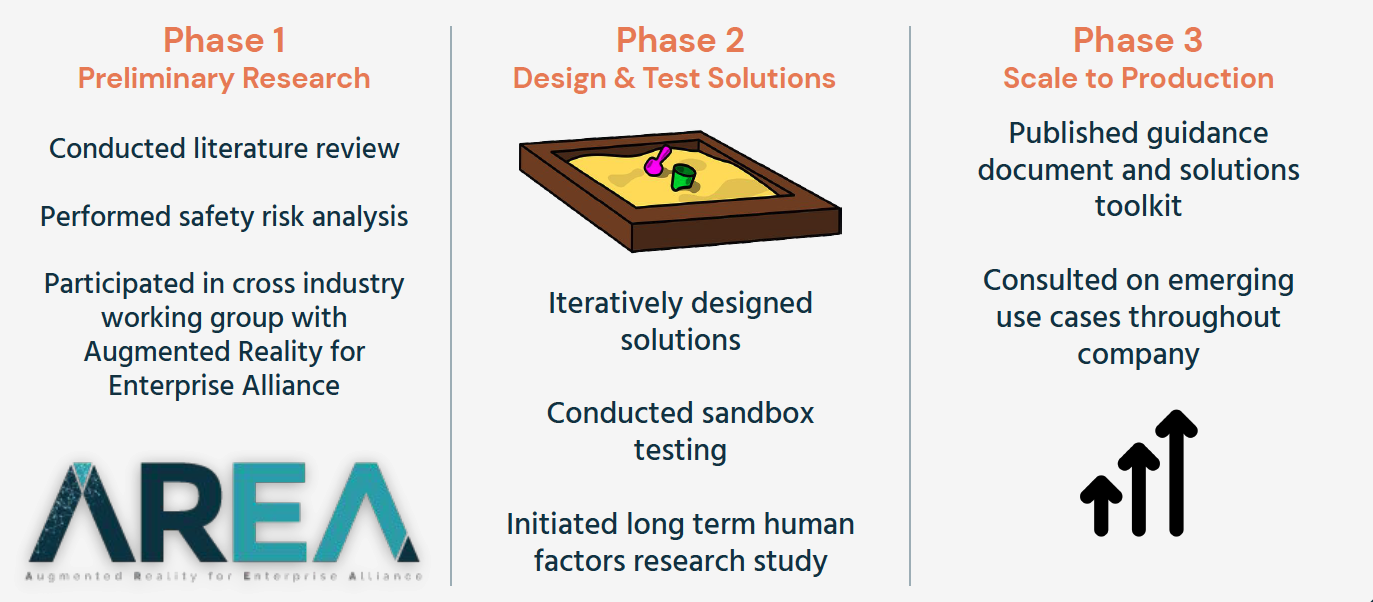

This project had an ambiguous path towards the final goal of scaling use of augmented reality technology across the company.

We followed an agile project methodology and utilized rapid prototyping techniques.

To be as succinct as possible, we felt like we had entered the innovation wild west, and we were responsible for figuring out the path to achieving the results our leaders wanted. Below is a high level summary that shows what research and activities were done during the course of this project.

Design Problems and Solutions

We encountered several safety, human factor, and ergonomic risks along the way. A sample of these risks and their solutions have been detailed below to demonstrate the type of design work I did on this project:

Hazard:

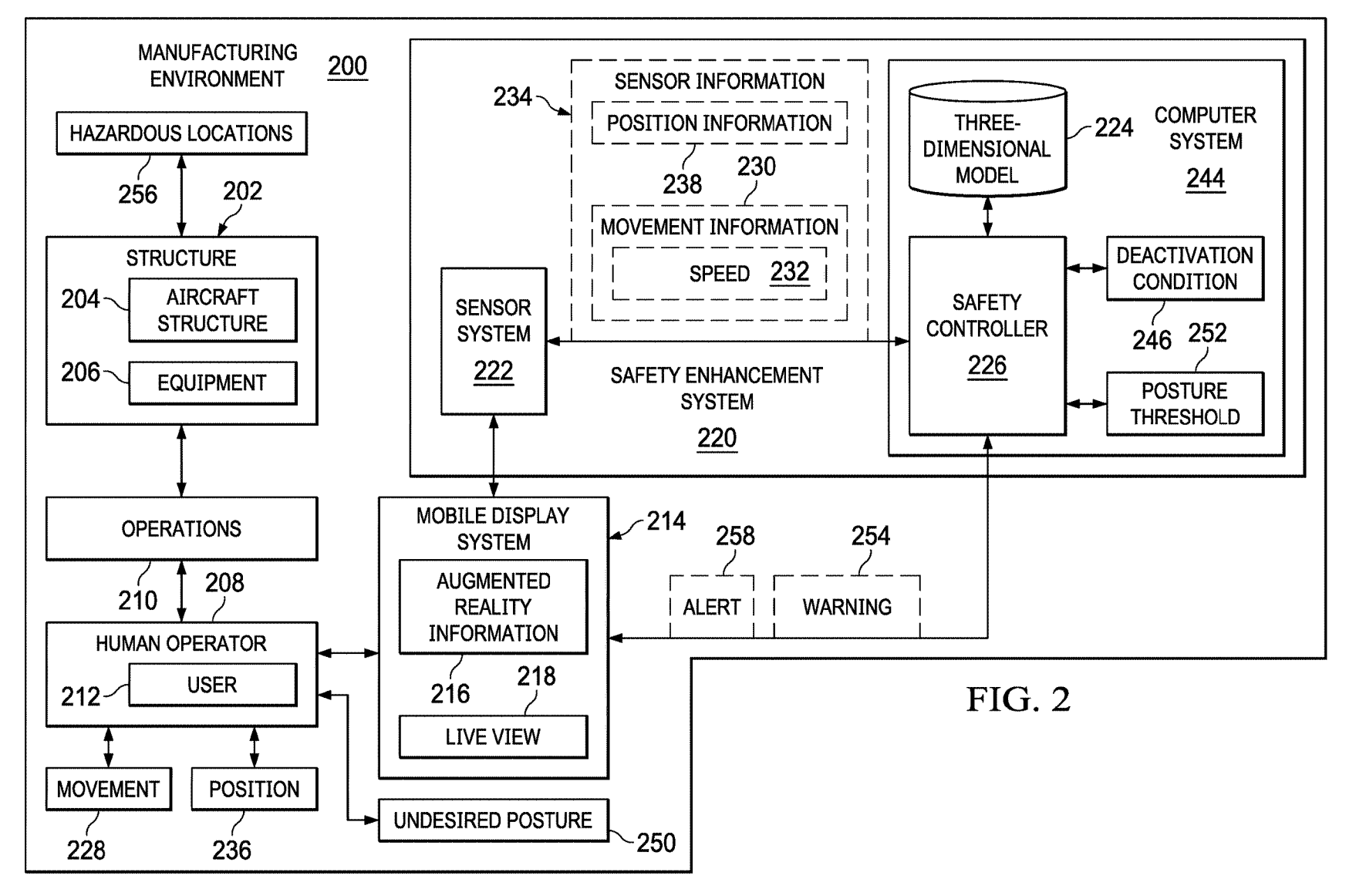

Obstructed line-of-site and limited situational awareness while using headset

Design Solution:

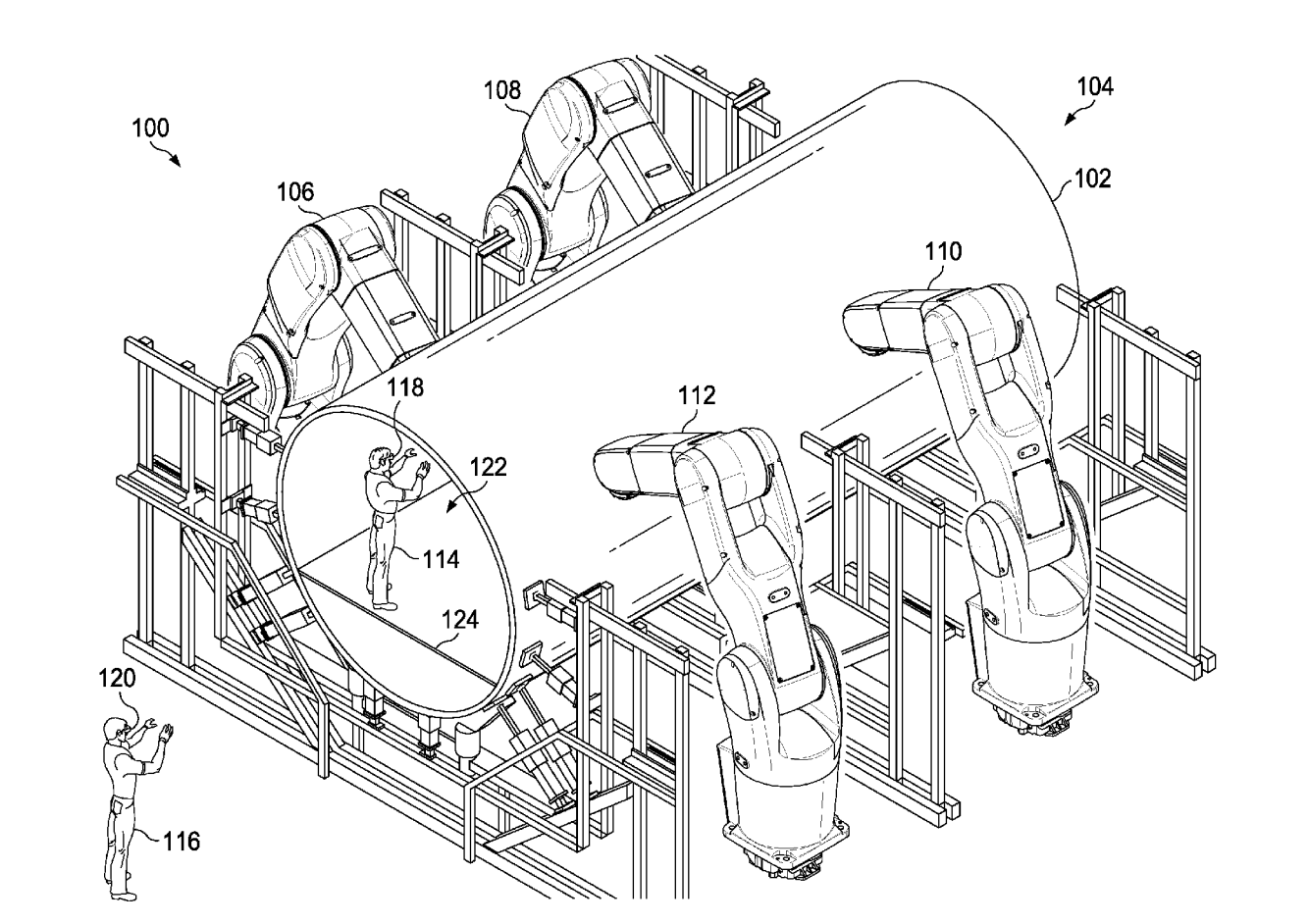

Created a software workflow that shuts off heads up display while user moves around aircraft (Patent Publication: US 20190287304 A1)

Hazard:

Head and eye protective equipment need to be designed for use with the headset, safety equipment required in manufacturing environment

Design Solution:

Collaborated with 3rd party vendors to design and produce solutions that integrate with headset and were comfortable for users

Hazard:

Some users presented with fatigue, nausea, and eye strain while using the headset for the first time

Design Solution:

Established break time schedule and prescribed targeted ergonomic exercises for users

Lessons Learned

Being on the cutting edge of innovation is exhilarating and a lot of fun.

If at first you fail, try again, be persistant and patient.

Teamwork is crucial to the success of big projects, comradery and inclusiveness can make the design process more effective.

You don't have to be the most experienced or educated in the room to be a design thinker.